Johnson Smart Flexible Packaging Automation Solutions (Johnson Flexible Automation)

Food & beverage, bakery, snack, dairy, and frozen-food factories are facing three demands at once: higher throughput, fast changeovers (many SKUs), and consistent quality. Conventional “fixed” packaging lines often struggle when pack formats change, leading to downtime and increased operating cost. Johnson Smart (Johnson Flexible Automation) focuses on flexible automation—a modular approach that integrates robots + vision + conveyors + packaging + palletizing to optimize end-of-line performance.

What value does Johnson Smart bring to factories?

Johnson Smart emphasizes a modular architecture and AI/vision detection to improve line flexibility—especially for plants that frequently switch products, pack sizes, and configurations. With modular design, manufacturers can start from a single robotic cell and scale into a complete line, expanding step-by-step based on CAPEX planning.

Key solution groups

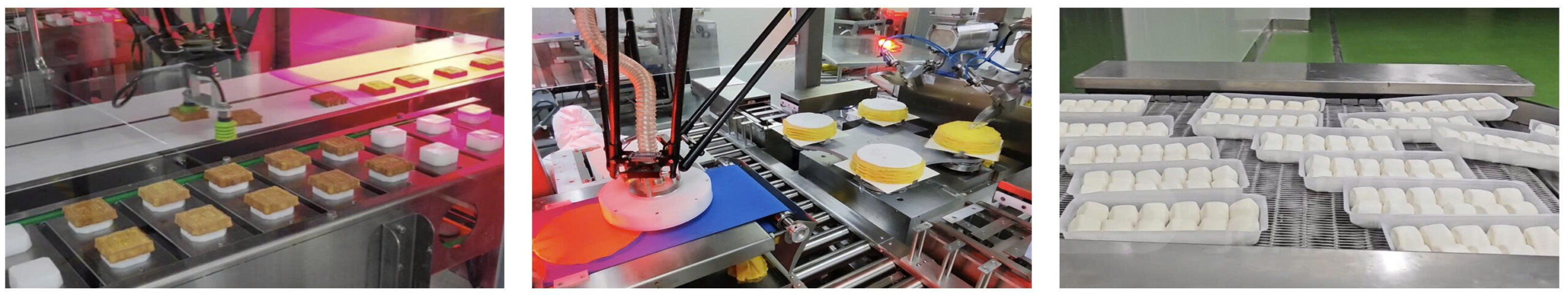

1) High-speed Robotic Pick-and-Place (Delta + Vision)

A core strength is delta robot pick-and-place for sorting, feeding, and placing—combined with vision to identify product position and orientation, even while moving on conveyors. Johnson Smart also mentions moving-object tracking, supporting accurate picking at high line speed.

2) Robotic Tray Loading: Vision-guided loading into trays/cases

Tray loading targets applications that place products into trays/cartons/cases on continuous conveyors. Vision supports precise positioning and can be extended to checks such as shape/color/dimension depending on the application. In practice, this is ideal for upgrading existing manual lines without rebuilding the entire system.

3) Robotic Case Packing: Modular top-load case packing

Johnson Smart provides modular case packing configurations that can combine picking, cartoning, case forming/packing, and downstream palletizing. The objective is an end-to-end approach for post-processing and end-of-line packaging—reducing reliance on manual labor while improving consistency.

4) Robotic Palletizing: Robot/cobot palletizing with fast pattern change

Automated palletizing improves safety and standardizes pallet quality. Johnson Smart describes PLC + HMI control, multiple layer pattern storage for quick format changes, and common safety options such as fencing, light curtains, interlocks, and E-stops. The system can also integrate modules like stretch wrappers, conveyors, labeling/traceability, and Industry 4.0 connectivity.

Representative case references (for context)

-

Frozen Tart Crust Packaging Line: integrates packaging + inspection + wrapping + palletizing; vision assists recognition and robots handle pick-and-pack at a stated 20 bags/min.

-

Multi-pack format handling (e.g., 6/12/24) highlights flexible robot units designed to support frequent SKU and configuration changes.

When should you consider Johnson Smart?

If your factory:

-

Runs many SKUs with frequent pack-format changeovers

-

Needs high speed while keeping gentle handling (especially bakery/snack)

-

Wants a scalable roadmap: start with a robotic cell and expand into a complete line (case packing → palletizing)

EFC Motion is the official local partner of Johnson Smart in Vietnam, supporting customers from solution consulting to on-site implementation. We work with your team to define throughput targets, SKU/changeover requirements, and layout constraints—then propose the right Johnson Smart configuration (robot + vision + packaging + palletizing) and a practical phased deployment roadmap for fast ROI.